Tank Bottom Valve

Sanitary ValvesTank Bottom Diaphragm Valve Actuated & Manual Type

Valve Size : 15mm to 100 mm Size (1/2" to 4")

Valve Type : 2-Way

Standard : BPE, 3A, DIN

Body MOC : Forged, SS 316L

Diaphragm MOC : EPDM + PTFE (10 Degree C to 150 Degree C)

Compliance with FDA 21 CFR 177.2600 and USP Class VI.

End Connection : Weld End, Clamp End,

Surface : SF1:ID polished to Ra≦0.5μm

SF4: EP finished to Ra≦0.38μm

Design Conform to ASME BPE standard

ID/OD mirror polished and

ID Ra ≦ 0.5 μm / OD Sand blasted

Pneumatic Actuator :

Actuator MOC : SS 304

Spring MOC : SS 304

Piston MOC : SS 304

Features

- Easy to clean & no corrosion problems.

- Precision design & machining for high torque out-put

- Low noise and smooth functions

- Auto control box available with various accessories.

- Multiple design available in diaphragm sampling valve

- Recommended for CIP & SIP system.

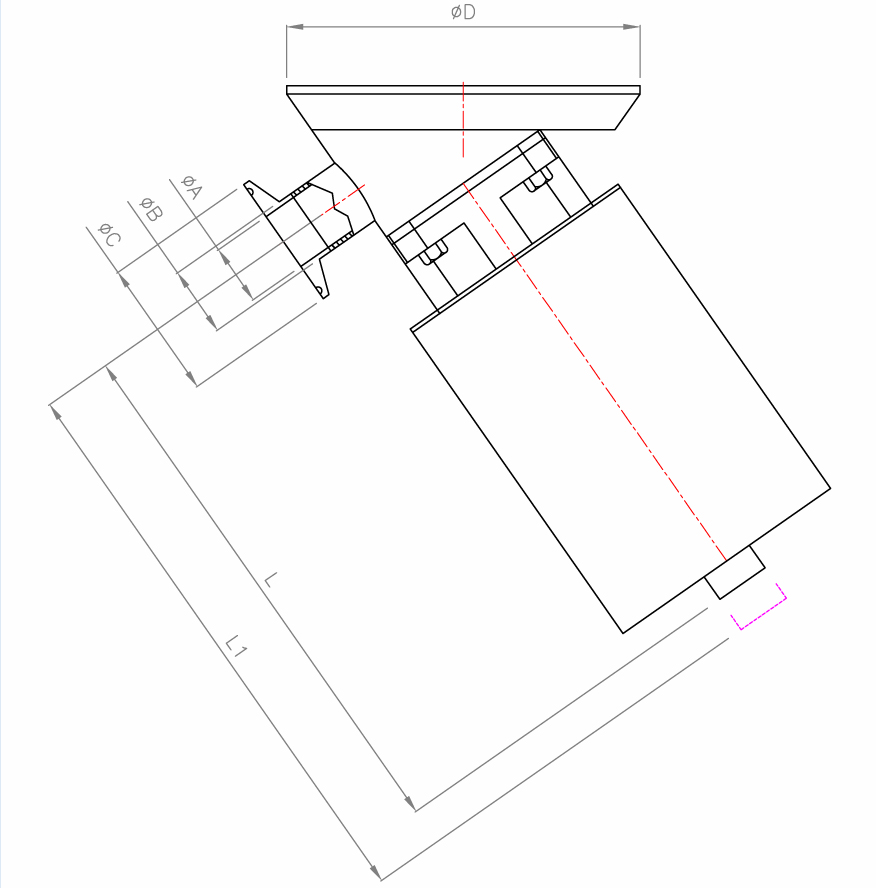

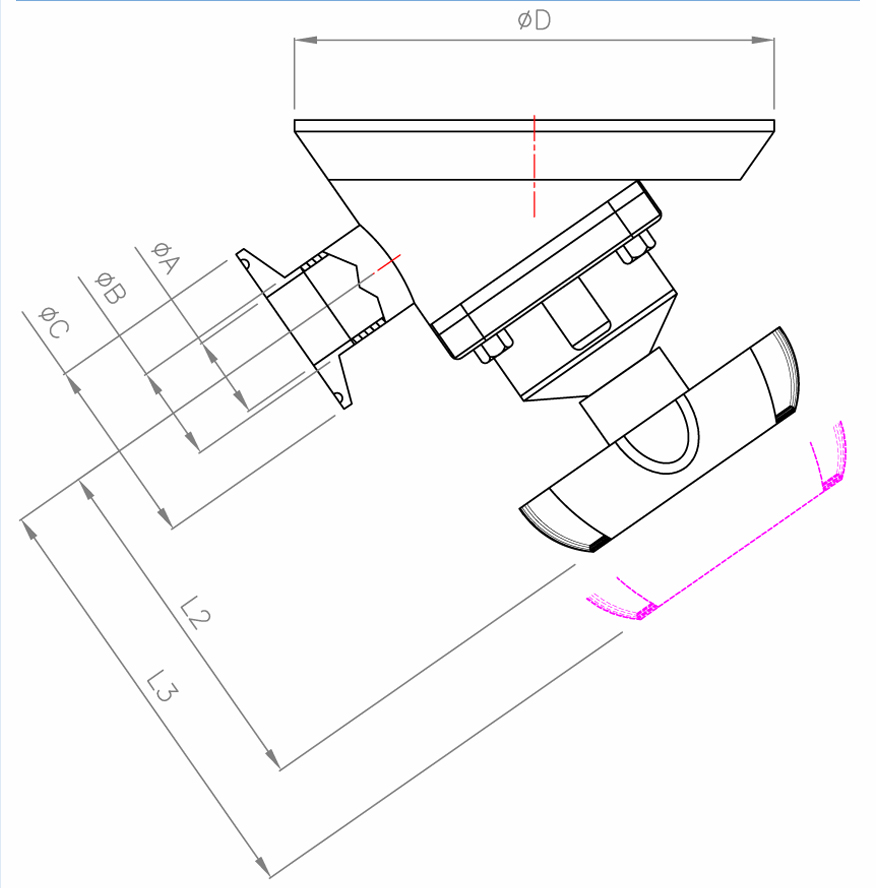

| TANK BOTTOM DIAPHRAGM VALVE | ||||||||

|---|---|---|---|---|---|---|---|---|

| SIZE | ØA | ØB | ØC | ØD | L | L1 | L2 | L3 |

| 1/2" | 9.4 | 12.7 | 25 | 100 | 122 | 131 | 74 | 83 |

| 3/4" | 15.75 | 19.05 | 25 | 100 | 122 | 131 | 74 | 83 |

| 1" | 22.1 | 25.4 | 50.5 | 120 | 212 | 225 | 100 | 113 |

| 1.5" | 34.8 | 38.1 | 50.5 | 160 | 217 | 232 | 119 | 134 |

| 2" | 47.5 | 50.8 | 64 | 160 | 315 | 333 | 135 | 153 |