Butterfly Valve

Sanitary Valves

Valve Size : 15mm to 100 mm Size (1/2" to 4")

Body MOC : SS 316L

End Connection : TC End, Weld End, SMS End, DIN End.

Auto Control Actuator for Butterfly Valve

Actuator MOC : SS 304

Spring MOC : SS 304

Cylinder MOC : SS 304

Auto Control Actuator Features

Shut-Off Time : 1.5 & 1.7 Second

Air Consumption : 0.266 Litre & 0.550 Litre at 5 Bar

Output Torque : 20N/M & 30N/M

Valve Position : Normally Open / Normally Close

Various Model available as per requirement

Auto Control box available with various accessories

Features

- Easy to Clean & No Corrosion Problems.

- Auto Control Box Available with Various Accessories.

- Recommended for CIP & SIP System

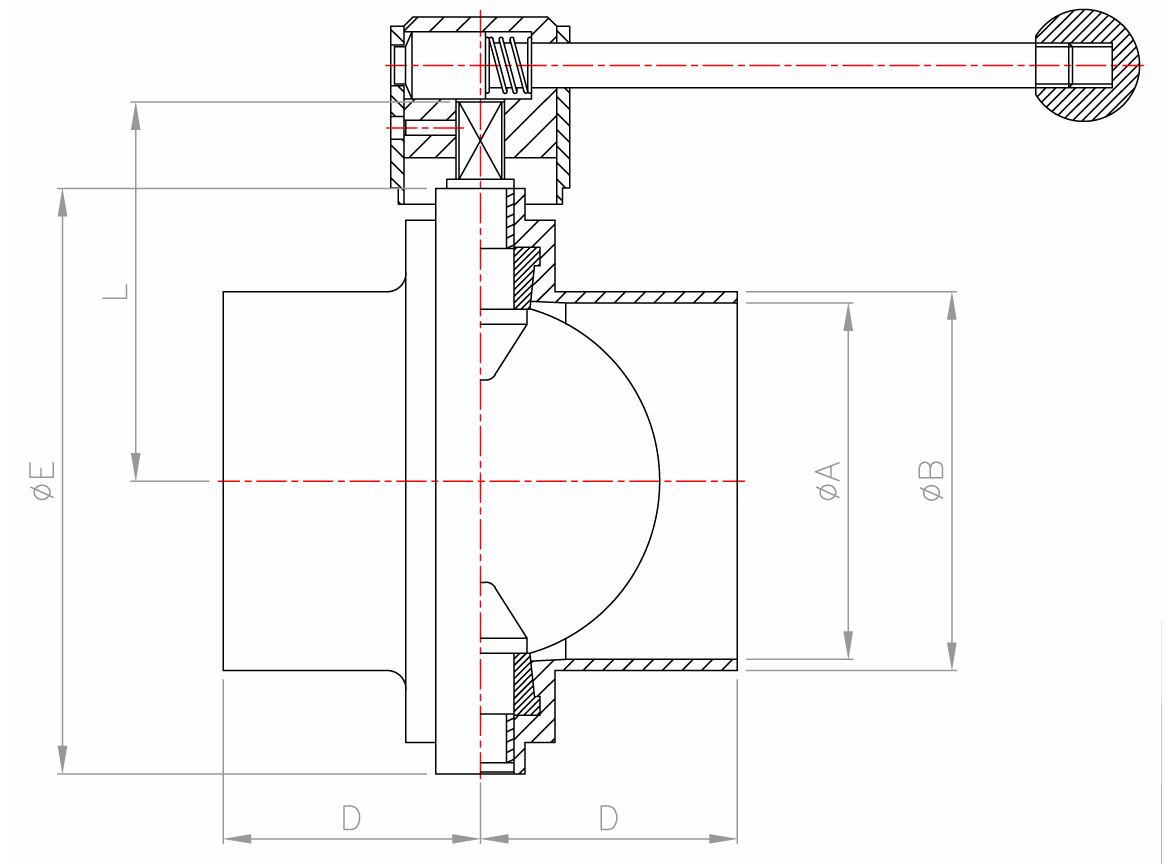

| BUTTERFLY VALVE | |||||

|---|---|---|---|---|---|

| WELD END | |||||

| 3A / BS | ØA | ØB | D | ØE | L |

| 1/2" | 9.4 | 12.7 | 34 | 79 | 61 |

| 3/4" | 15.75 | 19.05 | 34 | 79 | 61 |

| 1" | 22.1 | 25.4 | 34 | 79 | 61 |

| 1.5" | 34.8 | 38.1 | 38 | 85 | 64.3 |

| 2" | 47.5 | 50.8 | 40 | 105 | 74.3 |

| 2.5" | 60.2 | 63.5 | 40 | 112 | 77.6 |

| 3" | 72.9 | 76.2 | 41 | 125 | 84.8 |

| 4" | 97.6 | 101.6 | 44 | 157 | 101.75 |

| 6" | 146.86 | 152.4 | 40 | 216.5 | 132.5 |

| BUTTERFLY VALVE | |||||

|---|---|---|---|---|---|

| CLAMP END | |||||

| 3A / BS | ØA | ØB | D | ØE | L |

| 1/2" | 9.4 | 25.2 | 34 | 79 | 61 |

| 3/4" | 15.75 | 25.2 | 34 | 79 | 61 |

| 1" | 22.1 | 50.5 | 33 | 79 | 61 |

| 1.5" | 34.8 | 50.5 | 33 | 85 | 64.3 |

| 2" | 47.5 | 64 | 35 | 105 | 74.3 |

| 2.5" | 60.2 | 77.5 | 35 | 112 | 77.6 |

| 3" | 72.9 | 91 | 38 | 125 | 84.8 |

| 4" | 97.6 | 119 | 38 | 157 | 101.7 |

| 6" | 146.86 | 166.87 | 70 | 216.5 | 132.5 |

| DIN WELD | |||||||

|---|---|---|---|---|---|---|---|

| DIN | A TYPE | B TYPE | D | ØE | L | ||

| ØA | ØB | ØA | ØB | ||||

| DN10 | 10 | 13 | 9 | 12 | 34 | 79 | 61 |

| DN15 | 16 | 19 | 15 | 18 | 34 | 79 | 61 |

| DN20 | 20 | 23 | 19 | 22 | 34 | 79 | 61 |

| DN25 | 26 | 29 | 25 | 28 | 34 | 79 | 61 |

| DN32 | 32 | 35 | 31 | 34 | 38 | 85 | 64.3 |

| DN40 | 38 | 41 | 37 | 40 | 38 | 90 | 66.7 |

| DN50 | 50 | 53 | 49 | 52 | 40 | 105 | 77.6 |

| DN65 | 66 | 70 | 66 | 70 | 41 | 125 | 84.8 |

| DN80 | 81 | 85 | 81 | 85 | 42 | 137 | 91.6 |

| Dn100 | 97.6/100 | 101.6/104 | 97.6/100 | 101.6/104 | 44 | 157 | 101.75 |