Sanitary Diaphragm

Sanitary Valves

All the diaphragms meet Sanitary and Pharmaceutical

Standards, Compliance with FDA 21 CFR 177.2600 and USP Class VI.

Diaphragm Valve Actuated & Manual Type

Valve Size : 15mm to 100 mm Size (1/2" to 4")

Valve Type : 2-Way

Standard : BPE, 3A, DIN

Body MOC : Casting, Forged, SS 316L

Diaphragm MOC :

EPDM + PTFE (10 Degree C to 150 Degree C)

Compliance with FDA 21 CFR 177.2600 and USP Class VI.

End Connection : Weld End, Clamp End,

Surface : SF1 : ID polished to Ra≦0.5μm

SF4 :

EP finished to Ra≦0.38μm

Design conform to ASME BPE standard

ID/OD mirror polished and

ID Ra≦ 0.5μm / OD Sand blasted

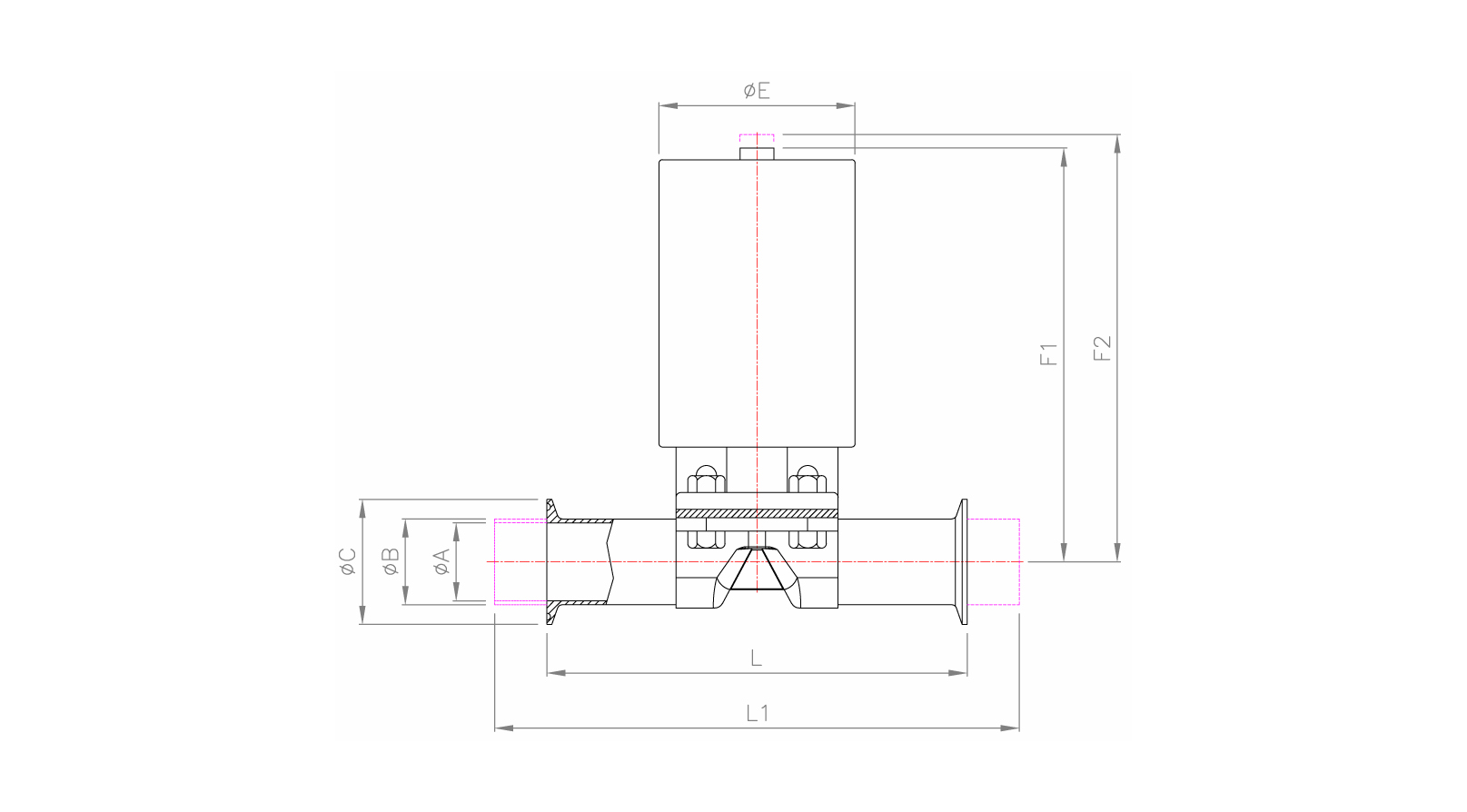

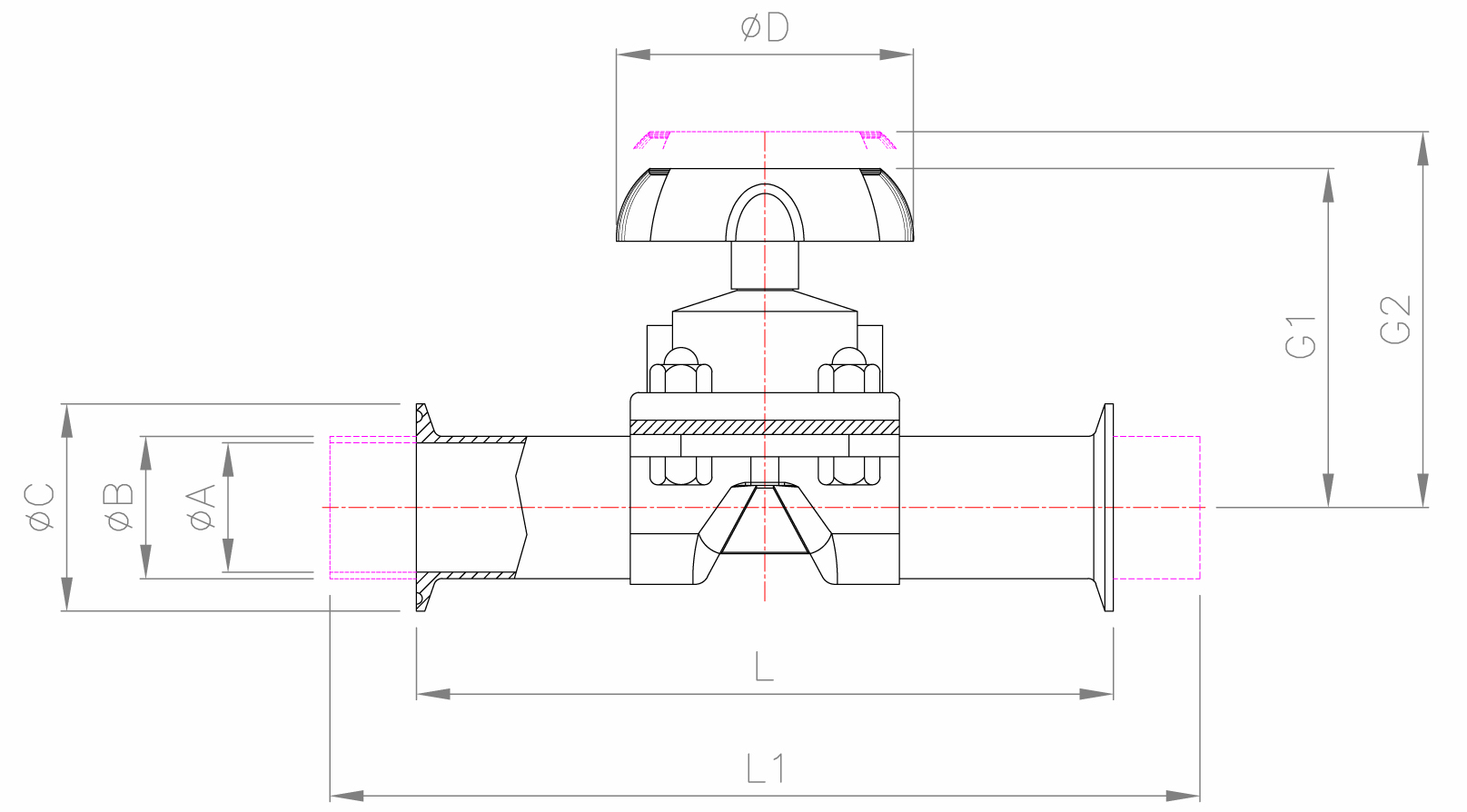

| BPE | 1" | 1/2" | 3/4" | 1.5" | 2" |

|---|---|---|---|---|---|

| ØA | 9.4 | 15.75 | 22.1 | 34.8 | 47.5 |

| ØB | 12.7 | 19.05 | 25.4 | 38.1 | 50.8 |

| ØC | 25 | 25 | 25/50.39 | 50.39 | 63.91 |

| ØD | 60 | 60 | 95 | 95 | 118 |

| ØE | 60 | 60 | 85 | 85 | 133 |

| F1 | 122 | 122 | 212 | 217 | 315 |

| F2 | 131 | 131 | 225 | 232 | 333 |

| G1 | 74 | 74 | 100 | 119 | 135 |

| G2 | 83 | 83 | 113 | 134 | 153 |

| L | 88.9 | 101.6 | 114.3 | 139.7 | 158.8 |

| L1 | 124 | 135 | 141.2 | 168.4 | 190.5 |

| DIN | DN10 | DN20 | DN25 | DN32 | DN40 | DN50 |

|---|---|---|---|---|---|---|

| ØA | 10 | 20 | 26 | 32 | 38 | 50 |

| ØB | 13 | 23 | 29 | 35 | 41 | 53 |

| ØC | 34 | 34 | 50.5 | 50.5 | 50.5 | 64 |

| ØD | - | 60 | 60 | 95 | 95 | 118 |

| ØE | 60 | 85 | 85 | 85 | 85 | 133 |

| F1 | 122 | 212 | 212 | 217 | 217 | 315 |

| F2 | 131 | 225 | 225 | 232 | 232 | 333 |

| G1 | 74 | 100 | 100 | 119 | 119 | 135 |

| G2 | 83 | 113 | 113 | 134 | 134 | 153 |

| L | 88.9 | 101.6 | 114.3 | 139.7 | 139.7 | 158.8 |

| L1 | 124 | 135 | 141.2 | 168.4 | 168.4 | 190.5 |

| DIAPHRAGM VALVE / ZERO DEAD VALVE / ASEPTIC VALVE | |||||

|---|---|---|---|---|---|

| 3A | 1/2" | 3/4" | 1" | 1.5" | 2" |

| ØA | 9.4 | 15.75 | 22.1 | 34.8 | 47.5 |

| ØB | 12.7 | 19.05 | 25.4 | 38.1 | 50.8 |

| ØC | 25 | 25 | 50.5 | 50.5 | 64 |

| ØD | 60 | 60 | 95 | 95 | 118 |

| ØE | 60 | 60 | 85 | 85 | 133 |

| F1 | 122 | 122 | 212 | 217 | 315 |

| F2 | 131 | 131 | 225 | 232 | 333 |

| G1 | 74 | 74 | 100 | 119 | 135 |

| G2 | 83 | 83 | 113 | 134 | 153 |

| L | 88.9 | 101.6 | 114.3 | 139.7 | 158.8 |

| L1 | 124 | 135 | 141.2 | 168.4 | 190.5 |