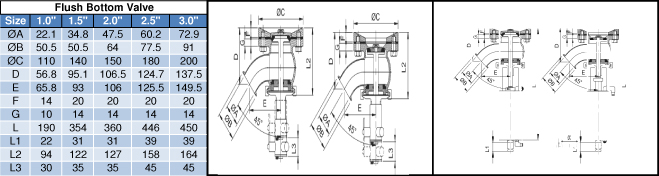

Flush Bottom Valve

Sanitary ValvesWorking principle

Flush Bottom Valve: the diaphragm provides body seal and seat seal. There is no path inside the external environment, so the valve is suitable for sterile environment. When the valve is closed, the pressure pad supporting the diaphragm moves toward the sealing surface on the valve body. As the pressure plate moves, the diaphragm bends and is forced toward the seat area in the center of the valve body, thus closing the flow path to the valve body. The relationship between the valve body and the pressure plate prevents the extrusion of the diaphragm.

Application

Flush Bottom Valve is a kind of pneumatic seat valve. It has sanitary and flexible design. Based on mature single seat valve design platform, few and simple moving parts make the valve very reliable and reduce its maintenance cost. The chute type channel makes the unloading more smooth and is used to cut off or open the pipeline to the storage tank. Widely used in Pharmaceutical, Dairy products, Beverage, Cosmetic and other industries.

Actuator Control mode

According to the site condition has the following three kinds of control mode, the reasonable selection of the control method can make your valves service life more longer, more convenient operation, cost savings.

1.Normally open type user:

Suitable for pneumatic valve in the working time longer occasion. When the valve is normally open spring does not load external gas source thrust, then the valve fatigue to a minimum. Because it is by the air pressure to close valve, so need filed air pressure stability, air supply reliable.

2.Normally closed type user:

Suitable for pneumatic valve is in the closed time working longer occasion. For depends on the spring to close, when air pressure to drive the piston push spring, valve open. So for the normally closed user this valve service life more long, gas more economical. At the same time when the air supply fails, the valve is in the closed state, this control state is the most widely used.

3.Double acting type user:

Double acting type refers to the two chambers can be input compressed air separately, realize the two-way movement of the cylinder, no spring in the cylinder, the valve opening and closing rapidly, and can be used for large stroke valve, because it is by air pressure to close valve, so need the field gas source stability, air supply reliable.

Material Specification

Contact Part:AISI 316L

Other Contact Parts:AISI 304

Plug Stem:AISI 316L with chromiun plated surface

Gasket for Flow Area :EPDM/SILICON/Viton (FKM)/PTEF

Other Seals :NBR and EPDM

Surface:Mirror/Stain/Sand Blasted

Technical Data

Max Production Pressure : 1000kpa(10 bar)

Temperature Range: -10°C +140°C(EPDM)