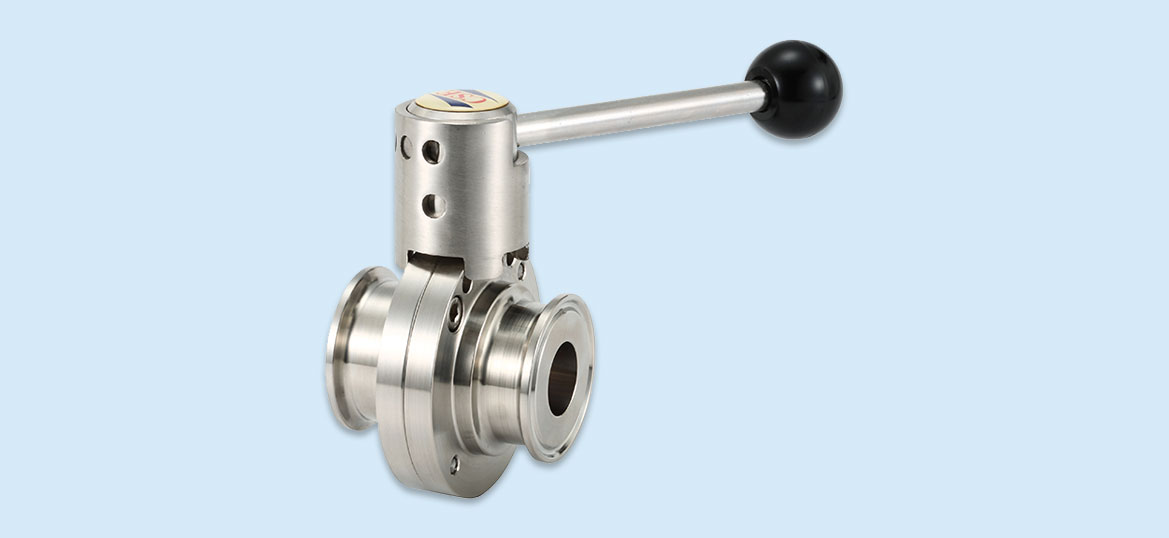

Pneumatic Actuator

Non-Sanitary ValvesActuator body MOC :

Extruded Aluminium alloy ( He30 ), it is

hard anodized to protect the internal & external components

from corrosion.

Operating pressure :

5 to 6 bar.

Actuator rotation :

0 to 90 degree turn rotation motion.

Actuator end caps MOC :

Die cast Aluminium are powder coated

to provides longer life cycle, against corrosion and reduces

wearing resistance.

Piston MOC :

Die cast Aluminium are equiped with slide guides

and seals in high engineered plastic. Pistons are identical on both

sides which allow reverse rotation simply by inverting the pistons.

Pinion (drive shaft) MOC :

Anti blow out proof alloy steel pinion is electroless nickel plated to reduce friction,

provide maximum wear resistance and protection against corrosion under severe conditions as it fully conforms to

the latest standards of ISO 5211, DIN 3337 Namur.

Position indicator :

All Actuator are equipped with regular position indicator showing the current state of the

Actuator and valves. On top of Actuator has a Namur slot to engage with all popular sensor, positioner and

accessories.

Seals :

NBR rubber o-rings provide trouble free operation at standard temperature ranges between -20 c to + 80 c

temperature range, for high & low temperature we can provide special material seals as per applications.

Fastner :

Stainless steel fastners are provided for long life corrosion resistance application.