Pneumatic Actuator Ball Valve

Non-Sanitary ValvesValve size : 15mm to 150 mm size (1/2" to 6")

Valve ratings : 150#

Body MOC : WCB, CF8, CF8M, CF3, CF3M (special alloy

on request.)

Ball MOC : SS 304, SS 316, SS 304L, SS 316L

End connection : Flanged end, TC end, Screwed end

Make : Neel industrial solution

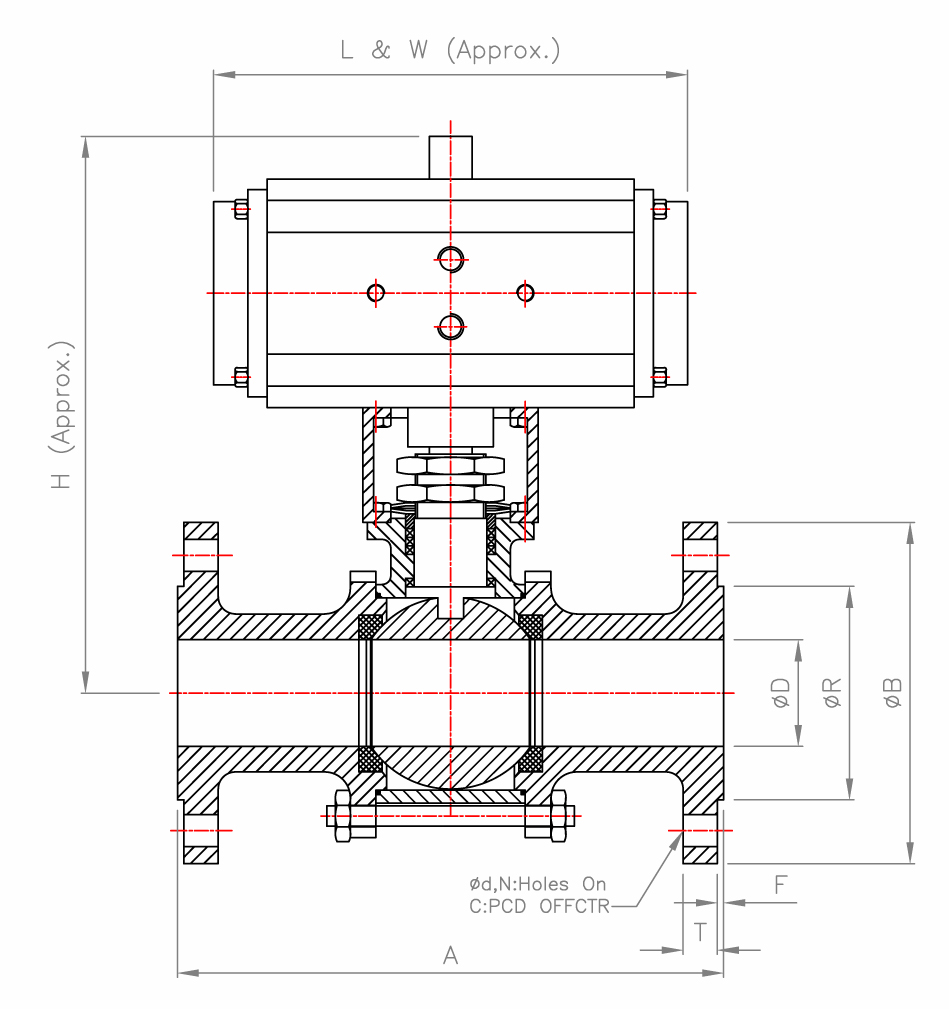

Ball Valve (Actuated & Manual) - Flange End

| BALL VALVE (ACTUATED & MANUAL) | ||||||

|---|---|---|---|---|---|---|

| SIZE | ØD | A | H | L | W | |

| 15 | 1/2" | 12.5 | 108 | 114 | 100 | 60 |

| 20 | 3/4" | 19 | 118 | 150 | 100 | 60 |

| 25 | 1" | 25 | 127 | 170 | 116 | 73 |

| 40 | 1.5" | 38 | 165 | 200 | 134 | 80 |

| 50 | 2" | 50 | 178 | 210 | 134 | 80 |

| 65 | 2.5" | 64 | 190 | 228 | 158 | 93 |

| 80 | 3" | 76 | 203 | 250 | 158 | 93 |

| 100 | 4" | 100 | 229 | 305 | 185 | 110 |

| FLANGE DIMENSIONS - 150# RF | ||||||||

|---|---|---|---|---|---|---|---|---|

| SIZE | ØB | T | ØR | F | Ød | N | C:PCD | |

| 15 | 1/2" | 89 | 11.2 | 35 | 1.6 | 16 | 4 | 60.5 |

| 20 | 3/4" | 98 | 11.2 | 43 | 1.6 | 16 | 4 | 70 |

| 25 | 1" | 108 | 11.2 | 51 | 1.6 | 16 | 4 | 79.3 |

| 40 | 1.5" | 127 | 14.3 | 73 | 1.6 | 16 | 4 | 98.5 |

| 50 | 2" | 152 | 16 | 92 | 1.6 | 19 | 4 | 120.5 |

| 65 | 2.5" | 178 | 17.5 | 105 | 1.6 | 19 | 4 | 139.5 |

| 80 | 3" | 190 | 19.2 | 127 | 1.6 | 19 | 4 | 152.5 |

| 100 | 4" | 229 | 24 | 157 | 1.6 | 19 | 8 | 190.5 |